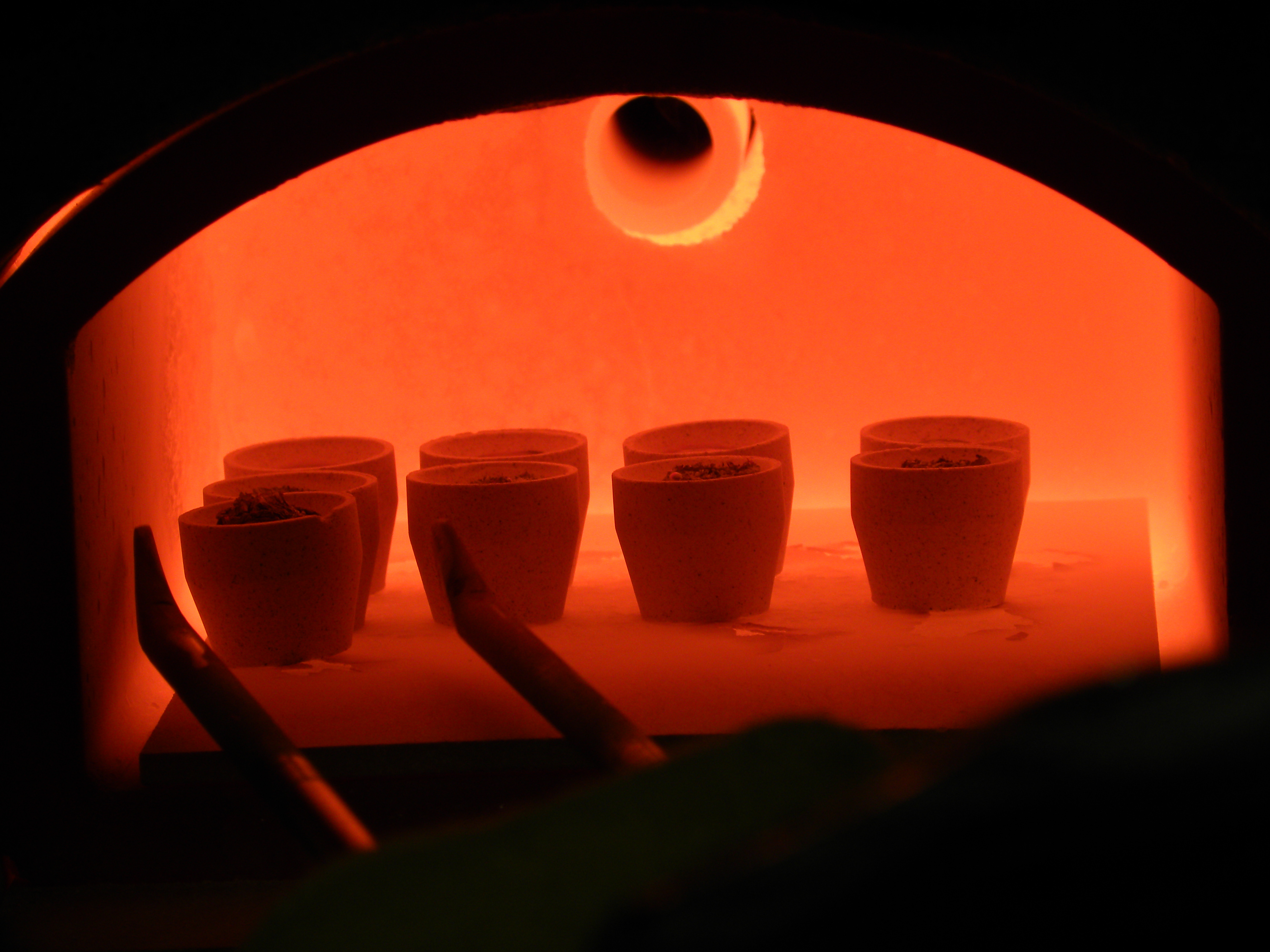

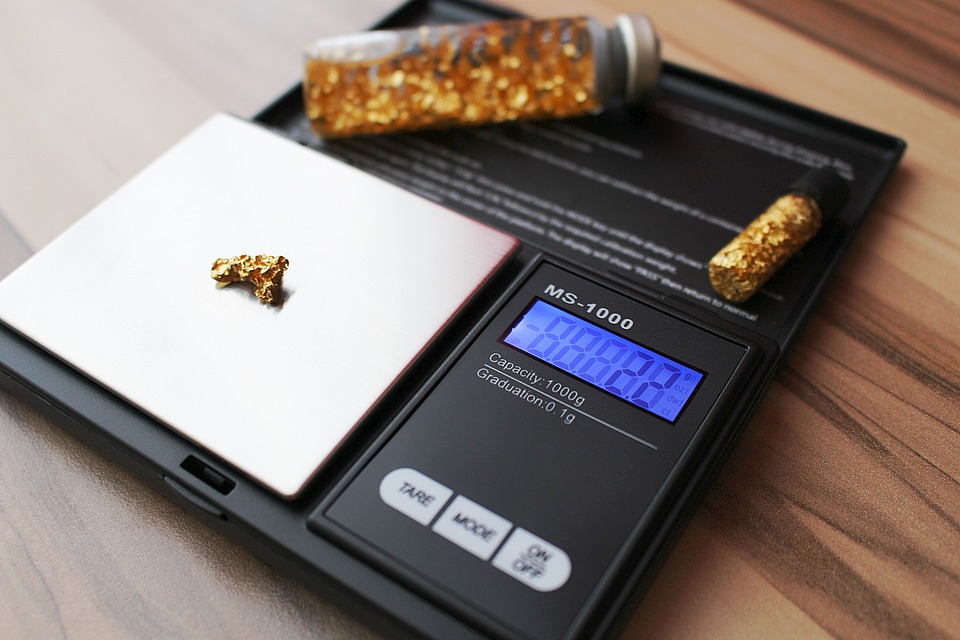

Gold Fixing has fusion departments equipped with last generation smelting systems; our ten-year partnership with other companies is fundamental for exchanging views in order to improve the manufacturing processes of all the metal alloys containing gold, silver, platinum and palladium.

Low frequency induction technology and temperature control enable us to produce precious metal alloys of higher quality.